Safety devices for machine tools for retrofitting

Protective devices – retrofitting protective devices for machine tools. Safety retrofitting in accordance with the Ordinance on Industrial Safety and Health.

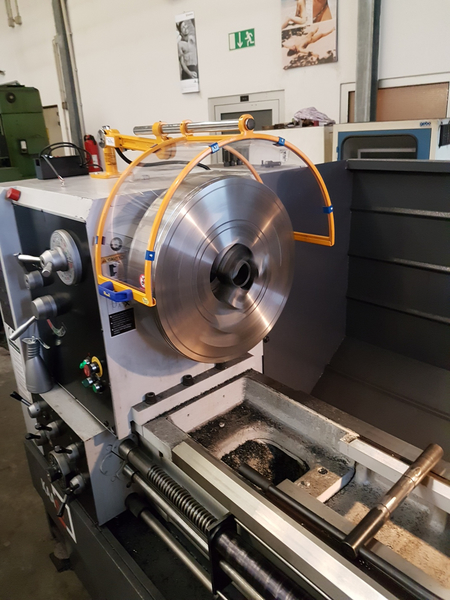

We offer retrofitting of guards and control devices for drilling machines, lathes, milling machines and grinding machines in accordance with current safety regulations (of any make).

The safety regulations and accident prevention regulations of the Industrial Safety Ordinance stipulate that machine tools must be equipped with protective devices such as an emergency stop button, lathe chuck protection, spindle protection, intervention protection and a restart interlock. The guards offered have been designed in such a way that they can be retrofitted to almost any machine with little effort in order to comply with the legally prescribed machine safety. We take care of the installation and electrical integration of the guards and control devices for you.

We offer mechanical and electrical integration for REPAR2 protective devices for many makes! You will receive a price quotation that takes all costs into account. At the end of the installation, we will work with the customer to check that all protective and control devices are working properly.

Each safety device is supplied with a CE declaration and test stamp.

REPAR2 Safety and machine cladding

CNC-Multiservice offers a wide variety of guards (sizes and shapes) for countless machine types

The safety guards can be easily retrofitted and fitted to almost any type of machine to ensure a safe working area and are always supplied with one or more safety switches. Our safety guards comply with the applicable safety regulations and the European Machinery Directive EN 2006/42/EC. In addition, our installations and warning notices are documented in a UVV protocol and visually displayed with a sticker. We carry out the annual inspections at a fixed price. We are also happy to advise you on your premises, directly on site at the machines.

Hacksaw

TSG 1 Carousel

FBB series model FP2 and Kunzmann

Model PT 600

Sample stands at our service center

Repar2 has been designing, creating and customizing protective devices for machine tools since 1970. In its modern factory in Gorla Minore (near Milan), the company offers a wide range of guards (standard or customized) for lathes, milling machines, grinders, drills, shaping machines, saw blades, tool grinders, presses, safety barriers, non-slip carpets and latest generation industrial LED lamps.

Repar2 is one of the leading companies in the machinery safety sector and exports its products to Europe and to all other countries in the world that have adopted the EC Machinery Directive, also thanks to its dense and highly specialized distribution network, in order to meet the needs of customers all over the world.

Repar2 participates in the most important international trade fairs directly or through its network of distributors and resellers specialized in security.

Repar2’s main goal is to continuously improve its products in order to provide its customers with a wide choice of standard products that are always available, easy to assemble and use and extremely user-friendly. Furthermore, Repar2 wanted to offer a product range with an excellent quality/price ratio.

The engineering of the guards is carried out using a CAD system in order to solve and fully meet all the customer’s specific requirements. Repar2’s standard or customized guards offer a robust construction of the highest quality, entirely Made in Italy and in strict compliance with the latest safety standards of the European Community.

REPAR2 complies with the Machinery Directive 2006/42/CE, updated with the standardized text on occupational health and safety Legislative Decree 81/2008.